Solutions for steel mills and the steel industry

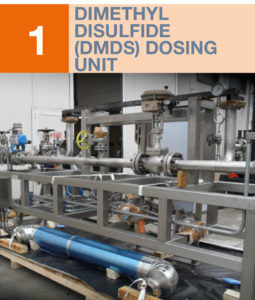

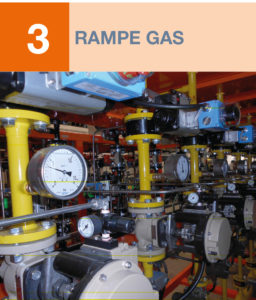

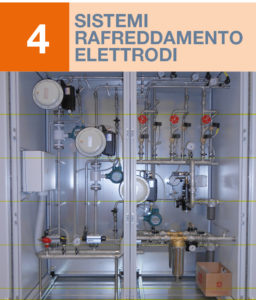

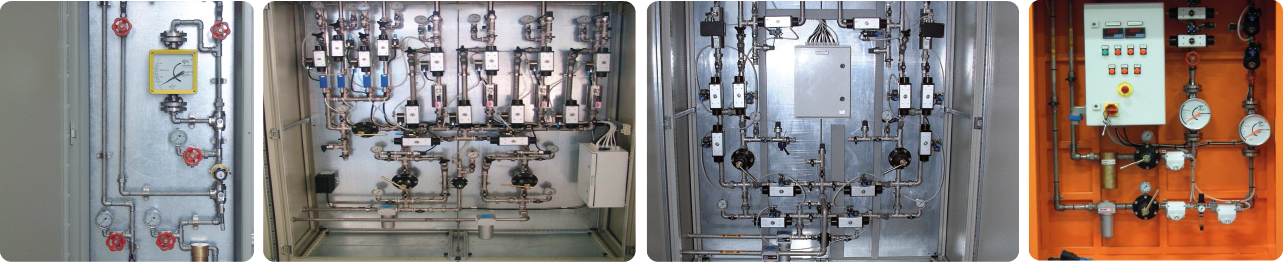

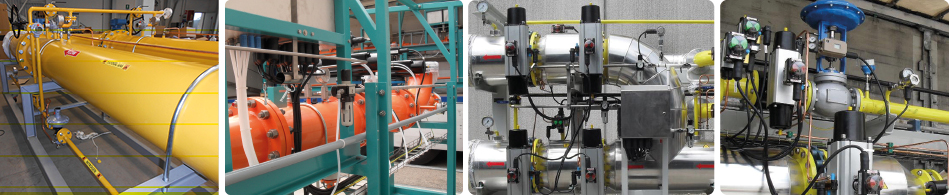

In the steel industry, we have more than 600 certified installations in more than 30 countries. Electro-instrumental gas dosing systems are built by highly qualified personnel and based on first-class instrumentation that meets all applicable standards.

They are located in the main Italian steel mills (plants in Brescia, Padua, Udine, Verona, Vicenza, Dalmine, Odolo, Lonate and Cremona) as well as in more than 30 countries in Europe, America, Asia and Africa.

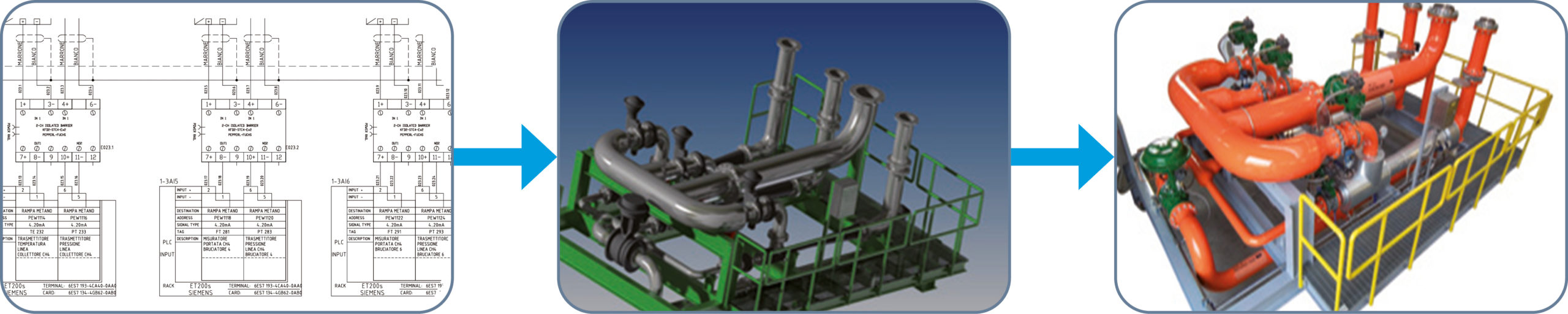

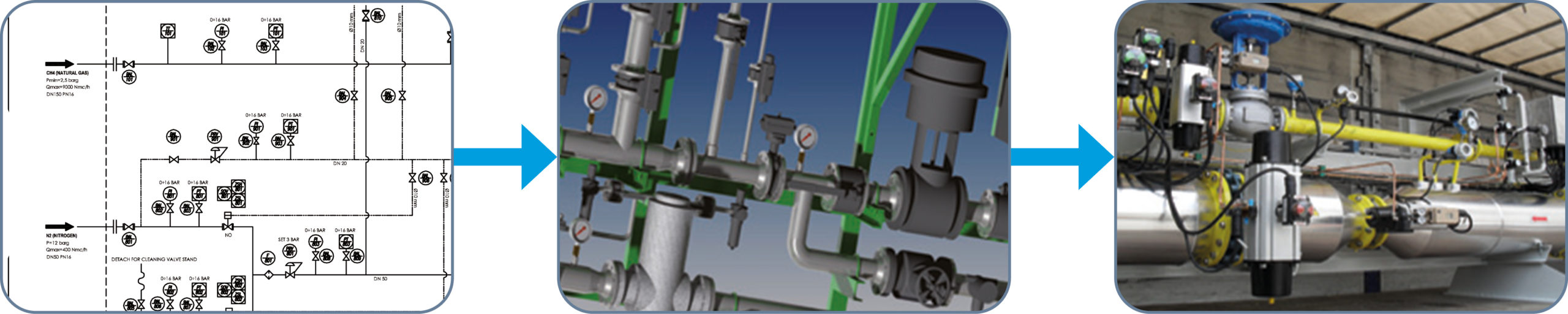

From P&I to turnkey plant

We support our customers by identifying, designing, and implementing the most suitable solutions in terms of technology, production, environment, and logistics. We have identified a valuable range of partnerships with leading instrumentation and design companies so that we can guarantee maximum integration of our solutions into existing lines. Our engineering department makes its experience available by realizing ad-hoc solutions guaranteeing a very quick return on investment.

Our offer for steel mills